Securall AG900 - Chemical Storage Locker, 308.1 Cubic Ft Storage Capacity; Dim: 8'4"H x 7'W x 7'D

Need Financing? Fill out this form with H.I.L Financial to get a fast approval!

Expert Support Available! 24/7 via Live Chat or Call Us +1 (816) 635-0030

Warranty & Part Replacement Policys

All equipment comes with a Limited or Lifetime Warranty!

Multiple Financing & Payment Methods

We accept ACH transfers, money wires and checks as alterative payment methods while also providing multiple financing options for customers.

Description

Securall offers a complete line of safety storage buildings specifically designed for storing agri-chemicals and equipment safely. All buildings are designed to help you comply with safety rules when mixing and handling pesticides. These specially designed buildings are perfect for Golf Courses, Farms, Nurseries, Greenhouses and Landscape Contractors. Securall buildings help reduce the risk of poisoning and injuries among pesticide handlers and agricultural employees and will also help you protect against chemical spills, children and animal poisonings, theft, fire and unauthorized personnel.

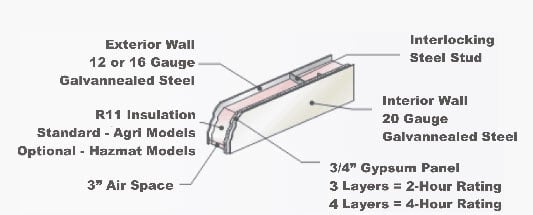

All Hazmat Storage Buildings are designed in accordance with the standards set forth by NFPA Code 30 and comply with OSHA and EPA regulations. The double wall construction contains 3" of air space throughout. Outer wall is constructed of all-welded 16 or 12 gauge steel. Inner wall is constructed of 20 gauge steel. All models are FM Approved for the storing and dispensing of combustible liquids. All electrical options are U.L. Approved & installations are compliant to current state approved NEC regulations.

Shelving & Lighting - Chemical Storage lockers/buildings comes with 3 tiers of shelving. Interior & Exterior lighting, a receptacle and load center.

Easy To Ship Securall's Chemical Storage Buildings (AG1200 and Below) are designed to fit in a standard high cube shipping container reducing shipping costs and labor time.

2 Hour Fire Rating Upgrade - Industry's 1st & Only Intertek Tested and FM Approved 2 hrs fire rated wall construction built with 1.5 hour fire rated roof construction, 1.5 hour fire rated door construction, and multiple layers of ¾” gypsum ultracode wallboard. Air inlet vents with UL Listed and labeled fire damper with louvers. Dampers have a galvanized steel frame, curtain-type galvanized steel blades and a UL Listed 165° F fusible link.

4 Hour Fire Rating Upgrade - Industry's 1st & Only Intertek Tested and FM Approved 4 hrs fire rated wall construction built with 3 hour fire rated roof construction, 3 hour fire rated door construction, and multiple layers of ¾” gypsum ultracode wallboard. Air inlet vents with UL Listed and labeled fire damper with louvers. Dampers have a galvanized steel frame, curtain-type galvanized steel blades and a UL Listed 165° F fusible link.

Easy To Ship: Securall's Chemical Storage Buildings (B1200 and below) are designed to fit in a standard high cube shipping container reducing shipping costs and labor time.

We are approved to install Damage Limiting Construction Panel on non rated and Fire Rated buildings.

Standard Features

-

Models AG200 through AG1200 Exterior Walls: 16 gauge galvannealed steel.

-

Models AG1600 through AG8000 Exterior Walls: 12 gauge galvannealed steel. .

-

Interior Walls: 20-gauge galvannealed steel (3" air space between walls).

-

R-11 Fiberglass insulation in ceiling and walls

-

GFCI Duplex receptacle with weatherproof cover

-

Steel shelving (3 Tiers) with raised edges

-

Dust Proof/Fluorescent Interior Light with Weatherproof Switch

-

Sump: 12-gauge steel liquid tight, continuously welded.

-

Grating: Removable galvanized steel (Optional)

-

Forklift channel: 12 gauge galvanized steel

-

Grounding: NFPA & OSHA Compliant Static ground connection inside and out on all explosion rated models

-

Labeling: NFR warning label, Hazard Ratings System, Instructions

-

Venting: Natural convection vents

-

Available with 2 or 4 hour fire rating

-

Chemical/corrosive/ultraviolet resistant paint

-

Removable galvanized steel safety floor planking

-

Moisture Resistant Exterior Light with Photocell

-

Reflective warning tape marking entryway

-

Safety Floor Planking

Slip resistant planking 9" wide, 12 gauge galvanized steel with raised perforated buttons and debossed holes protruding down. Galvanized steel floor planking above sump area for maximum corrosion resistance. Floor planking designed to sustain a minimum uniformly distributed load of 250 pounds per square foot. Floor planking and supports are removable to facilitate sump cleaning in the event of a spill. -

Door Style

Door for AG200-AG400 Provide one (42" wide x 62.5”) and B600-B1200 Provide one (42” wide x 80”) high door to facilitate the unloading and loading of hazardous material within the building. Installed with a UL Classified commercial grade keyed lockset. The door shall serve as personnel entrance and exit.Door for AG1600-AG8000 Provide one 60” wide x 80” high double door to facilitate the unloading and loading of hazardous material within the building. Installed with a UL Classified commercial grade keyed lockset. The double door shall have one active leaf to serve as personnel entrance and exit. The active leaf must be equipped with a door closer available on AG600-AG1200 fire rated models.

-

Factory Mutual System Approval

Securall Fire-Rated Hazardous Material Storage Buildings carry the Factory Mutual System Approval label and are constructed based upon UL Fire Resistance Ratings classification criteria. In addition, all Fire-Rated Buildings come with hydraulic operated self-closing, fire-rated doors and fire damper protected vents

Attributes

| Approvals | NFPA - Designed in accordance with specifications set forth by the National Fire Protection Association, UL - Include UL listed electrical accessories, Complies with EPA & current OSHA regulations, FM-Factory Mutual Approved |

|---|---|

| Capacity | 308.1 Cubic Ft Storage Capacity |

| Dimension (H x W x D) | 8'4"H x 7'W x 7'D |

| Fire Rating | No Fire Rating |

| Limited 15 Year Warranty | Yes |

| Quote Only | Yes |

| Regulations | FM-Factory Mutual Approved, NFPA - Designed in accordance with specifications set forth by the National Fire Protection Association, UL - Include UL listed electrical accessories, Complies with EPA & current OSHA regulations |

| Sump Capacity | 154 Gal. to hold (9) - 55 Gal. Drums |

| Use Cases | Chemical Storage Locker |

| Warranty | 15 Year Structural Limited |

Paint Color

The interior and exterior finish consists of an aliphatic polyurethane finish. This polyurethane coating has chemical properties to withstand salt spray, chemical rub, fading due to UV exposure, and other tests performed to epoxy paints. Urethane is more durable under conditions when moving items in and out of the cabinet as it resists chipping and peeling. Unless some other color is specified, cabinets will ship in designated standard color. For custom colors, customer must provide a paint chip.

Flammable & Combustible Classes

NFPA FLAMMABLE & COMBUSTIBLE CLASSES

| FLAMMABLES | FLASH POINT | BOILING POINT |

| Class IA | <73°F (22.8°C) | <100°F (37.8°C) |

| Class IB | <73°F (22.8°C) | >=100° F |

| Class IC | <73°F (22.8°C) and <100°F (37°C) | >100° F |

| COMBUSTABLES | FLASH POINT | BOILING POINT |

| Class II | 100° F (37.8° C) ≤ FP < 140° F (60° C) | - |

| Class IIIA | 140° F (60° C) ≤ FP < 200° F (93° C) | - |

| Class IIIB | 200° F (93° C) ≤ FP | - |

9.5.1 The volume of Class I, Class II, and Class IIIA liquids stored in an individual storage cabinet shall not exceed 120 gal (460 L).

9.5.2 The total aggregate volume of Class I, Class II, and Class IIIA liquids in a group of storage cabinets shall not exceed the maximum allowable quantity of flammable and combustible liquids per control area based on the occupancy where the cabinets are located.

* NFPA 30 Flammable and Combustible Liquids Code, 2011 Edition. Section 9.5.1, 9.5.2

FM Approved Fire Rating

Fire Rating According to FM

Securall Fire-Rated Storage Buildings (8'4"H X 42'W X 9'D Max Dimensions) carry the Factory Mutual System Approval label and have an FM Approved Fire Rated Wall & Roof Design. Wall and Roof are Tested at Intertek Testing Laboratories. Securall Fire-Rated Storage Buildings constructed based upon UL Fire Resistance Ratings classification criteria. Standard models are available in 2-hour and 4-hour fire ratings. Wall ratings are either 2 or 4 hour fire rated . Roof ratings are either 1.5 or 3 hour fire rated (Check with your local authority having jurisdiction for correct wall/roof rating needed). In addition, all Fire-Rated Buildings come with hydraulic operated self-closing, fire-rated doors and fire damper protected vents.

Industry's 1st & Only Intertek Tested and FM Approved 2 Hour Fire Rated wall construction built with 1.5 hour fire rated roof construction, 1.5 hour fire rated door construction, and multiple layers of ¾” gypsum ultracode wallboard. Air inlet vents with UL Listed and labeled fire damper with louvers. Dampers have a galvanized steel frame, curtain-type galvanized steel blades and a UL Listed 165° F fusible link.

Industry's 1st & Only Intertek Tested and FM Approved 4 Hour Fire Rated wall construction built with 3 hour fire rated roof construction, 3 hour fire rated door construction, and multiple layers of ¾” gypsum ultracode wallboard. Air inlet vents with UL Listed and labeled fire damper with louvers. Dampers have a galvanized steel frame, curtain-type galvanized steel blades and a UL Listed 165° F fusible link.

Please check with your local authority having jurisdiction for setback requirements and correct wall/roof rating needed.

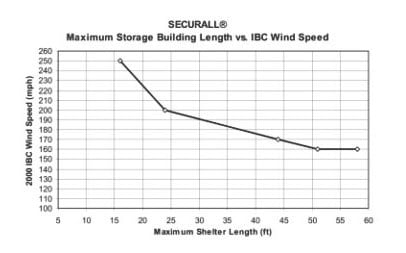

Hurricane Resistant Wall Design

Securall Buildings have been tested to determine the amount of force they can withstand and were shown to withstand F-4 tornado force winds of 250 mph. The chart below demonstrates the wind speed that a particular length of wall will resist.

Upgrade package is available for Tornado Resistant Walls.

Securall Hazamat Storage Buildings are all-welded using 12 gauge (B/AG1600X-B/AG8000X Models) and 16 gauge (B/AG200X-B/AG1200X Models) galvannealed steel outer walls and 20 gauge cold rolled steel inner walls provide maximum durability, weather resistance, and rigidity.